“Anodized” refers to a process called anodizing, which is an electrochemical process used to coat the surface of a metal with a protective and decorative oxide layer. This process is commonly used on metals such as aluminum, titanium, and magnesium.

During anodizing, the metal object is immersed in an electrolyte solution and serves as the anode (hence the term “anodizing”). A direct electric current is passed through the electrolyte, causing oxygen ions to combine with the metal ions on the surface of the object. This creates a stable oxide layer that is tightly bound to the metal surface.

The anodized layer provides several benefits. It enhances the metal’s corrosion resistance, making it more durable and less prone to rust or other forms of degradation. Anodizing also improves the metal’s wear resistance and hardness. Additionally, the process allows for the introduction of various dyes or pigments into the oxide layer, resulting in a wide range of colors and aesthetic options.

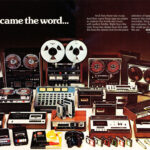

Why are anodized aluminium tape recorder reels a good idea?

Anodizing aluminum is a popular choice for tape recorder reels due to its specific advantages and properties.

Firstly, anodizing provides enhanced corrosion resistance to the aluminum surface. The anodized layer acts as a protective barrier, preventing the underlying metal from coming into contact with moisture, chemicals, and other corrosive substances. This is especially beneficial for tape recorder reels, as they may be exposed to various environmental conditions, such as humidity or accidental liquid spills. The anodized coating helps ensure that the reels remain in good condition over time, reducing the risk of corrosion-related damage.

Secondly, anodizing increases the hardness and wear resistance of aluminum. The process creates a dense and durable oxide layer on the surface of the metal, making it more resistant to abrasion and wear. This is advantageous for tape recorder reels because they typically experience frequent contact with the tape, which can cause friction and wear. Anodizing helps to mitigate the effects of such wear, extending the lifespan of the reels and maintaining their performance.

Moreover, the anodizing process allows for the introduction of various dyes or pigments into the oxide layer. This means that anodized aluminum can be produced in a wide range of colors, providing aesthetic options for tape recorder reels. The ability to customize the appearance of the reels can be particularly appealing for manufacturers who want to match the reel color with the overall design of their tape recorders or to offer different visual options to customers.

In addition to these benefits, anodizing is a relatively cost-effective and environmentally friendly process. The electrochemical nature of anodizing allows for efficient and precise coating of aluminum surfaces, reducing material waste. Furthermore, the use of electrolyte solutions in anodizing can be carefully controlled and managed to minimize environmental impact.

Overall, anodizing aluminum for tape recorder reels offers excellent corrosion resistance, improved wear resistance, and the ability to customize the appearance. These factors make anodized aluminum a practical and aesthetically pleasing choice for manufacturers and users of tape recorders.